Lace Making

Machines:

Work Process

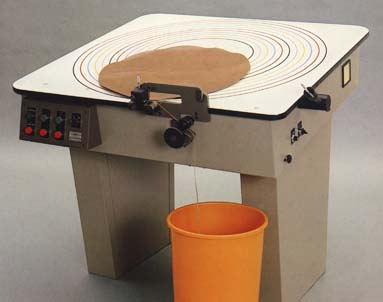

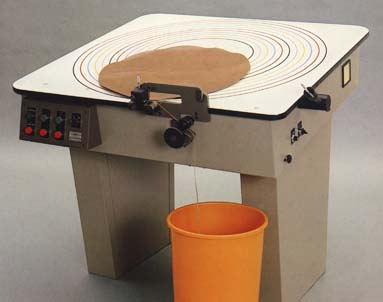

A skin is placed and centered on the machine. It is then perforated with the tripoint situated in the

center, and the exterior edge of the leather is then brought towards the knife. The skin is then rotated

and a circle is obtained. A bin will collect the excess material. Once a circle is obtained the machine

will begin to cut the lace to the desired width chosen by the operator. The lace will be pulled by two

transportation wheels located after the blade. When the machine is stopped and then restarted it will

simply resume from where it stopped. Cutting widths between 1.2 mm and 18.5 mm are available

upon request. The maximum skin cutting diameter is 104 cm, but you can order a wider cutting table as

an option which allows for a diameter of 150cm. The cutting speed is variable from 10 to 150 m/min.

Cutting Thickness for Version I is from 0.5 to 8mm. For Versions II & III it is 0.3 to 4mm according

to the type of leather. Version II cuts hard and soft leathers, vegetal, semi-chrome, and full-chrome

tanned. Version III cuts the same as Version II plus very soft leathers such as nappa, suede, etc.

|

|

Net Weight: 210kg/220kg Gross Weight: 280kg/300kg Dimensions: 136 x 136 x 56 cm